COTS for military power without the hidden costs

By Christian Jonglas, Technical Support Manager, GAIA Converter

Reliability and performance are absolute requirements in electronic systems for defense applications. Engineers in the sector have traditionally met these needs by using highly customized designs assembled from discrete, military-specification components, resulting in bespoke power supplies through a lengthy and expensive process.

However, governments in places like Europe and the US have encouraged military users to prioritize cost-effectiveness in procurement and, to that End, to utilize commercial off-the-shelf (COTS) products whenever possible.

In the case of DC/DC converters for military or avionics applications, the COTS path offers numerous end-user benefits, primarily because it provides standard, ready-to-use, multiple applications-oriented products. The use of mass-produced commercial off-the-shelf (COTS) parts is cost-effective, offering versatile components that can be configured in either distributed or centralized power supply formats. They can be used and qualified in a broad range of different applications, drastically shortening development times compared to the custom approach.

However, simply dropping into COTS converters for avionics and military power supplies requires careful analysis, as some specific barriers and requirements must be met.

COTS issues

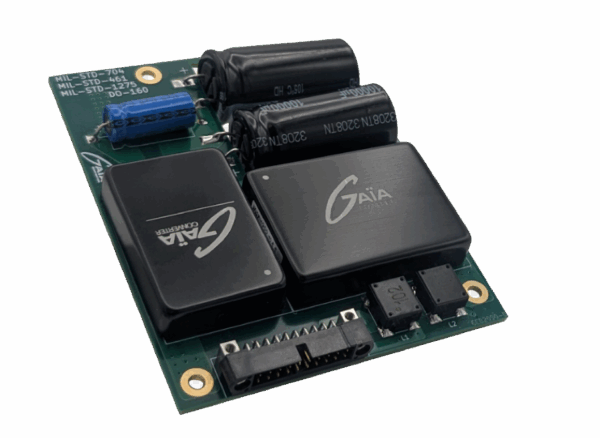

So, let’s take a look at the special requirements for high-reliability military COTS. The issues fall into four major categories: input and efficiency requirements, electromagnetic compatibility, environmental performance, and the specific needs of military and avionics systems. These problems can be overcome by employing a modular design approach, such as that adopted by GAIA Converter. This allows the use of COTS technologies where they offer the best performance. It also enables the use of additional components and subsystems to meet the specific requirements of military-grade systems.

Input requirements

Power inputs for military electronics can come from a variety of sources during operation, as the need arises to provide backup power from batteries when onboard generators cannot supply sufficient energy. The resulting changeovers in running systems can lead to significant fluctuations in input voltage, accompanied by brief, transient spikes. A secondary effect of these changes is a drop in efficiency if the converter was not designed from the beginning to handle input voltages well above or below nominal.

It is a challenge to design a power supply subsystem that can handle voltage changes from 9 to 80V, for example, and still provide a stable or constant conversion efficiency compatible with military needs. Many COTS converters are designed to work at their highest efficiency at nominal voltage. These products sometimes use variable-frequency topologies to support zero-voltage switching across the input voltage range.

Whilst variable frequency switching can render the noise less predictable and thus more challenging to mitigate, the implementation of Zero-Voltage Switching (ZVS) can significantly reduce the level of noise, often to the extent that it becomes less intrusive to sensitive systems such as radar and radio receivers. However, it is worth noting that variable frequency may also introduce stability issues, particularly when the load is subject to variations such as Pulse Width Modulation (PWM) or pulsed loads.

Moreover, the efficacy of tuning out conducted Electromagnetic Interference (EMI) is contingent upon the DC/DC converter featuring a synchronization function, which allows for a slight adjustment of the noise frequency to avoid interference with the bandwidths of radar or radio systems. This feature is common in many of GAIA Converter’s products. Regarding high-frequency soft-switching, it should be clarified that while it can improve efficiency, it does not categorically eliminate the need to manage efficiency across the entire input voltage range.

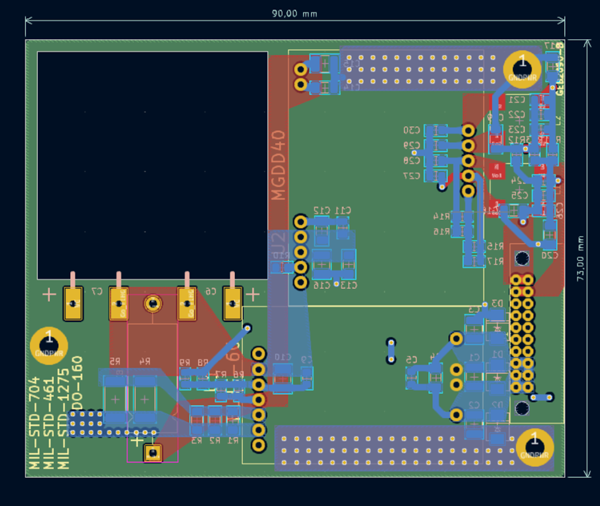

Transient and EMI protection

A broad input range can obviate the need for front-end voltage transient limiters, which are designed to manage transients and can otherwise diminish overall conversion efficiency compared to a conversion topology that inherently accommodates transients. In military applications, significant transients may arise from scenarios such as engine cranking or during the transition between disparate energy sources. According to the Mil-Std-1275 standard, a cranking level at 12V is stipulated, which the GAIA Converter MGDD series can comfortably support, given that they commence operation at a threshold of 9V, thus providing a considerable margin. Additionally, at the higher End of the input range, the MGDD series can easily handle the 80V/100ms surge imposed by the DO-160 standard, thanks to its capability to operate across a 9 to 80V input range.

A related problem arises from undervoltage and brownouts that can occur when energy sources fluctuate or due to intermittent faults. The interruption could last from 10ms to as long as 1 second. Military standards test for the ability to withstand these outages. COTS supplies designed for mainstream markets are unlikely to have the required resilience. However, it is possible to create this into supplies by combining an appropriate power-conversion topology with additional modules. For example, a common technique for increasing hold-up time is to place a large capacitor in the circuit to deliver a charge large enough to temporarily sustain the rest of the system. However, a simple COTS design using this approach risks creating large inrush currents when the energy source is restored. A technique pioneered by GAIA uses a boost voltage across the capacitor. This provides a larger amount of energy storage for a given capacitance. This maximizes hold-up time while reducing inrush-current problems.

Modular design techniques, such as those employed by GAIA’s power architectures, provide a mechanism for dealing with larger transients. They enable the combination of specialist military circuit design with advanced technologies found in commercial off-the-shelf (COTS) implementations. Numerous military standards from organizations worldwide enforce stringent controls on transients and electromagnetic interference (EMI).

An example is DefStan-461 from the UK, which stipulates that ground-based equipment with a nominal supply voltage of 28V must be capable of withstanding a surge of up to 202V (28V nominal plus a 176V surge) for 300ms. This presents a challenge to any circuit topology. However, the use of specialized front-end filters provides a means to clamp this voltage to an acceptable value, thereby handling this energy and protecting the rest of the system.

A combination of defense-focused designs in the core circuitry and the use of modular front-end filters provides the ability to meet the demands of relevant standards. Most radiation usually emanates from the input cabling or load circuitry, and that is where careful system design is essential, taking into account the circuit topology and grounding strategy, as well as shielding and cabling.

By employing high-frequency fixed switching in the core design, power converter designers can ensure a predictable frequency, simplifying the task of filtering out low-frequency conducted emissions and thereby facilitating compliance with stringent emission standards.

GAIA’s approach encapsulates the circuitry with metal on five sides. The system designers then have the option to complete the shield on the sixth side using a PCB ground shield under the converter.

Environmental performance

The packaging design is as crucial to the environmental performance of a military power converter. Where many COTS power supplies can utilize an open-frame design, these often perform poorly in defense applications due to the stresses of shock and vibration. Another technique not widely used in COTS designs is the use of potting to encapsulate individual components within the package. To ensure high reliability in vibration-prone environments, power converters designed for the defense sector extensively utilize potting. Such potting compounds, if chosen for their ability to conduct heat as well as insulate against vibration, can also enhance internal thermal conduction. In the case of GAIA’s modules, the technique simplifies design because the case-to-ambient thermal resistance can be specified for an entire brick within a modular power supply.

Keeping pace with technology

As with environmental factors, longevity and long-term reliability are key requirements for military components that are not best served by mainstream commercial off-the-shelf (COTS) products. Although the reliability of the components used plays a crucial role, an associated issue is the longevity of the design. Mainstream COTS products often have much shorter production lifetimes than the length of defense contracts and their equipment. As a supplier to the defense sector, GAIA has maintained continuity, even with its first DC/DC converter, a product introduced to the market in 1993.

While mainstream COTS hardware may have limitations in defense applications, these can be mitigated through modular design approaches, such as those employed by GAIA-Converter, which also facilitate the integration of emerging technologies. Wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), have gained traction in sectors like automotive and renewable energy due to their low switching losses and high conductivity when in operation. SiC, in particular, offers high robustness and reliable operation at elevated temperatures. These attributes enable increased operational frequencies, resulting in the development of high-density, high-power modules.

However, GAIA Converter currently does not utilize SiC or GaN technologies in their products, which are designed for relatively low voltage (28V nominal) and low power (less than 500W), as these wide-bandgap semiconductors are not yet technically competitive with the best MOSFETs for such applications. Nonetheless, it is anticipated that as these technologies continue to proliferate in the high-voltage automotive sector, they will eventually become more prevalent in low-voltage and low-power domains, a trend that GAIA Converter is closely monitoring for future designs.

Conclusion

As we have seen, the trend toward using COTS components and subsystems in the defense sector presents several challenges. However, by engaging with suppliers who recognize the limitations of these products, along with a fundamental understanding of the needs of military projects, it is possible to leverage the technological advances and the learning curve that accompanies mass production. This combination brings innovation and forward-thinking to applications that need high reliability and longevity. Suppliers such as GAIA-CONVERTER play a crucial role in applying these concepts to shape the future of military and avionics power systems.