Redefining Performance per Watt in Mobile Edge System Designs with COM-HPC Mini

By Dan Demers, regional vice president Americas, congatec

In mobile edge applications, success is no longer measured by raw compute performance alone. What matters is how much performance can be delivered per watt — and per square centimeter of board area.

Whether the platform is a rugged field robot, a mobile mapping system or a drone, the efficiency of the compute determines how far that device can travel, how much it can carry, and how reliably it functions over its deployment lifetime.

However, today’s embedded edge systems are no longer limited to simple control loops or low-resolution data capture. In a typical mobile edge application, you can expect to find:

- One or more cameras for high-resolution image or video capture and streaming

- On-device AI in support of tasks such as object recognition, obstacle avoidance, and simultaneous localization and mapping (SLAM)

- Secure connectivity for high-bandwidth data exchanges — not just remote control

- Additional applications, e.g., safety monitoring or predictive analytics

All of this requires high-performance local computing that reduces reliance on the cloud and delivers on real-time requirements. Of course, the trick lies in delivering the performance an application requires under the constraints of a mobile design limited by size, weight, power, thermal dissipation, cost, and other factors.

When Performance Becomes the Bottleneck

Selecting a host processor for a mobile edge system isn’t the same as choosing a discrete component. Rather, it defines the entire system envelope: If a processor’s performance per watt is too low, a chain of consequences — that may include one more of these — quickly follows:

- Reduced range resulting from faster battery drain

- Increased size and weight to accommodate larger batteries

- Increased size and weight to accommodate thermal management solutions like fans or heatsinks

- Reliability risks associated with insufficient thermal management

- Increased cost if additional compute (ASICs or dedicated accelerators) or high-speed PCB materials and design are required

- Feature limitations if sensors or applications must be removed to support power budgets

Let’s look at the requirements of a mid-size drone. This example system has four HD cameras running AI-based obstacle detection, SLAM, and live mapping. Such a hefty list of requirements can quickly exceed the capabilities of a conventional small form-factor embedded processor module — and that’s before considering any additional applications or subsystems that the module must support.

Presented with the wrong processor and memory combination, designers may need to accept shorter flight range or start adding co-processors that compound power and thermal management issues. Either way, the end product is less competitive on the market.

The same design principles apply to mobile robots, portable medical devices, industrial edge platforms, and more. In each case, the ceiling is only as high as that which the performance per watt per area can deliver.

COM-HPC Mini: SWaP-C Optimized, Available Off-the-Shelf

Alternatively, the same drone design team could choose an off-the-shelf computer-on-module (COM) in a reduced form factor to start their design. The COM-HPC Mini standard was created specifically for these performance-per-watt tradeoff scenarios, supporting processor thermal design power (TDP) up to 100 W in a footprint of just 95 mm × 70 mm.

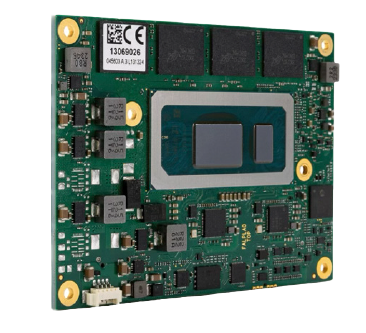

The congatec conga-HPC/mRLP is one example of a COM-HPC Mini module that delivers high compute density in a tight power budget. See figure 1. Its onboard 13th Gen Intel Core processor is a heterogeneous multicore processor available in extended temperature variants. The device contains between one and six Performance cores and four-to-eight Efficiency cores, where Performance cores support the execution of AI or application software and Efficiency cores manage communications, control, and the like.

The 13th Gen system on chip (SoC) also integrates Intel Iris Xe graphics. With up to 96 execution units for offloading multimedia-intensive workloads from primary cores, it adds performance without increasing size, power consumption, or cost — a major contrast with a discrete accelerator.

High-bandwidth I/O interfaces native to the COM-HPC Mini specification — PCIe Gen 4/5, USB4, and MIPI CSI — deliver data from high-fidelity sensors and between the processor and memory in support of real-time compute, onboard sensor fusion, and local autonomous decision making.

While each functional area in the system could require separate processors — and could potentially demand different modules altogether — the COM approach consolidates them into a single module. For drone system designers, the reduced performance per watt per area results in longer flight time, more robust feature sets, and an overall more competitive product.

Upward Mobility at the Edge

Innovation in the technology market will continue its march toward greater performance at lower power consumption and cost. Fortunately, mobile edge system designers can now leverage the benefits of COM-HPC Mini platforms to speed time to market on pre-validated, off-the-shelf platforms that are easily upgradable for long-term viability.

Access to a robust performance per watt per area profile is especially important to mobile edge system designers, who continuously balance their application’s demands with SWaP-C constraints. Fortunately, COM-HPC Mini platforms are readily available for design and deployment.

Looking to boost SFF drone capabilities? Learn more about the congatec COM-HPC Mini ecosystem at congatec.com.