How Liquid Flow Through Modules Work Reliably in Rugged Environments

TECHNICALPAPER

Learn how nVent SCHROFF adopted the VITA standard 48.4 to create a liquid cooling solution designed for thermal management of electronics operating up to 300 W while ensuring liquid does not come in direct contact with circuit boards.

Introduction

The advancement of Artificial Intelligence in military applications along the movement towards more electronic warfare are forcing multicore processors to operate at much higher speeds. However, due to SWaP requirements, processors and electronics must stay within the same footprint to avoid large redesigns of vehicles and aircraft. Traditional cooling methods of air or conduction cooling do not dissipate heat fast from this increase computing power enough to protect these vital electronics.

nVent SCHROFF has utilized over 20 years of liquid cooling expertise and adopted the VITA 48.4 standards to create a liquid flow through module designed to provide better heat dissipation. This paper will examine how nVent SCHROFF was able to develop this solution that is easy to upgrade within current infrastructure.

Whataretheindustrystandards aroundliquid cooling?

Before understanding how nVent SCHROFF was able to develop a solution, it is important to understand the framework of liquid cooling standards the military industry developed, as any liquid around electronics can lead to device failure quickly. That risk only increases in rugged environments.

VITA 48 is a standard developed by the VMEbus International Trade Association (VITA) that defines mechanical specifications for ruggedized systems, particularly focusing on cooling methods for embedded systems used in harsh environments. VITA 48 is one of several open standards integrated into the U.S. DoD’s Sensor Open System Architecture (SOSA). The alignment between VITA 48 and SOSA supports the creation of rugged, high-performance systems that are modular, interoperable, and thermally optimized for harsh environments.

VITA 48’s cooling and mechanical standards provide the critical thermal management infrastructure that SOSA systems rely on to meet performance requirements in military and aerospace applications. By utilizing VITA 48 cooling methods, system designers can create more versatile, efficient, and upgradable systems.

The 48.4 standard focuses on liquid flow through cooling. Below is an overview of the VITA 48.4 standard.

- Method: Liquid coolant is circulated through a cold plate or channels in the module, which draws heat away from the components.

- Usage: Suitable for systems requiring very high levels of heat dissipation, such as high-power computing or signal processing applications.

- Advantages: Provides superior heat dissipation compared to air or conduction cooling; ideal for extremely high-performance systems.

- Cooling Capacity: Approximately 300+ watts per slot.

- Factors Influencing Capacity: Coolant type (e.g., water/ glycol, dielectric fluids), flow rate, and cold plate channel design.

The nVent SCHROFF Solution

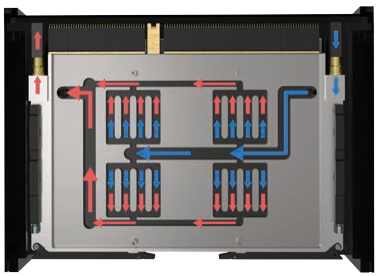

As processor numbers and locations can different per application, nVent SCHROFF develops a flow through path that is unique to each printed circuit board (PCB), ensuring coolant is transferring over the processor to absorb the heat.

ThenVentSCHROFFengineeringteamwillusein-housethermal simulationstocreateaflowpaththatpr

ovidesthemostoptimal heat dissipation. Once the flow path is determined, the custom designed flow path is an aluminum cooling plate offered in multiple finishes. A cover is brazed, laser welded, or friction stir wielded in place to the cooling plate, creating a barrier between the liquid and electronics.The flow path is in accordance with VITA 48.4 specifications and the 1″ pitch is aligned with the SOSA technical standards for 3U/6U form factors.

To connect the module to the liquid cooling/coolant aboard a vehicle, nVent SCHROFF uses quick disconnects that are compliant with VITA 48.4 standards and interoperable with any= 48.4 chassis. The quick disconnects are leak proof ensuring no coolant is lost between the chassis and module. Their vibration resistance helps to keep the connection secure in extreme movements of the vehicle.

Additional Securing Features

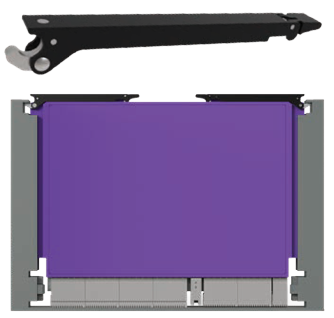

Simply having a module with a liquid flow through path is not enough to meet the VITA 48.4 standards. Additional components are needed to secure the module in place within the chassis, avoiding the traditional threats of shock and vibration as well as addressing the additional threat of liquid leakage.

nVent SCHROFF has developed the 311 Series Inserter/ Extractor the provides self-compensation for board tolerance. The HF311-TC series fits onto the 6U board that maintains positive pressure on the connectors, further securing the transfer of liquid between the chassis and module meeting the VITA standards.

Known worldwide for the Calmark & Birtcher lines of board retainers, nVent SCHROFF has a variety of modified Commercial-of- the-Shelf (COTS) designed to meet the needs of any PCB module. Due to greater need of clamp force to protect the PCB against shock and vibration, nVent SCHROFF would recommend its High Clamp (HC) Force series of Card- Loks. With its shallower angles, the HC series provides up to 3x the clamping force compared to a standard series.

Conclusion

Introducing liquid into any military electronic device could present failures during mission critical activities. nVent SCHROFF’s 20 years of liquid cooling expertise and following the guidance of industry standards like VITA and SOSA greatly mitigates or even eliminates these risk. From the quick discounts, to the laser welded plating, to the additional security of Card-Loks and Inserter/Extractors, nVent SCHROFF is able to provide a complete module ready to be quickly integrated into any 48.4 Chassis.