Ready for Anything: HUMS and Predictive Maintenance

![]() By Marc Steiner, CEO, Advanced Defense Technologies, Inc. (ADTI)

By Marc Steiner, CEO, Advanced Defense Technologies, Inc. (ADTI)

The U.S. military is under immense pressure to keep its equipment operational. From aircraft to submarines and armored vehicles, our troops rely on a diverse range of equipment for personal safety and mission success. Sustaining this equipment is not just a matter of national security, but one of ultimate consequence.

As a result of ongoing operational demands, the military is frequently using its equipment far longer than expected, and demand for replacement parts outpaces the industrial base’s capability to produce them. Simultaneously, budget pressures and personnel shortfalls are reducing the number of trained maintainers available at the tactical edge.

The traditional, planned maintenance model, or worse, waiting for equipment to break before fixing it, is no longer viable. To overcome current equipment maintenance challenges, the Department of Defense is turning to predictive maintenance.

The Shift to Predictive Maintenance & How HUMS Fits In

Predictive maintenance involves using data gathered from equipment to anticipate when components will wear out or fail, thereby reducing downtime, extending the lifespan of tools, and cutting costs associated with emergency repairs or unnecessary part replacements.

By analyzing usage patterns, environmental conditions, and performance indicators, predictive systems can identify issues early and prevent safety risks. For a military force operating in complex and contested environments, this is critical.

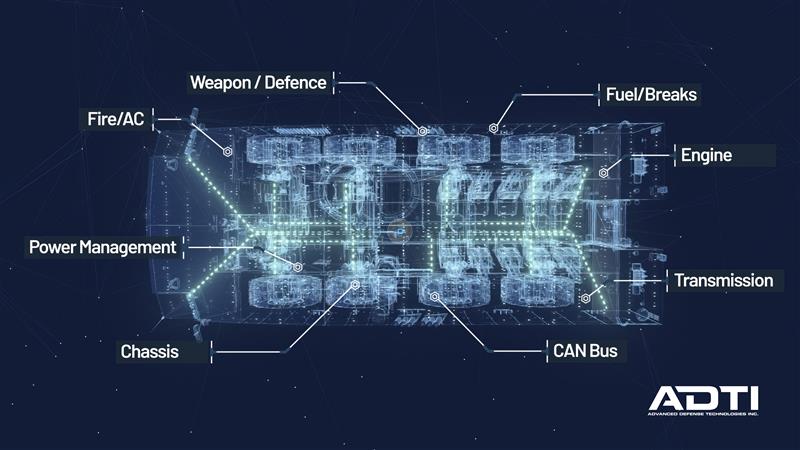

A key enabler of predictive maintenance is the Health and Usage Monitoring System (HUMS). HUMS is an onboard diagnostic system that collects, processes, and reports on data from sensors embedded throughout military equipment. These systems provide real-time feedback on the mechanical health of critical subsystems and integrate that data to assess the equipment’s overall status.

HUMS monitors key variables, including temperature, vibration, and load stress. When combined with predictive analytics platforms, this data can determine when a part is likely to fail, identify systems under abnormal strain, and indicate how long a platform can operate safely before requiring maintenance.

With these insights, the military can shift maintenance from time-based schedules to condition-based decisions. For example, instead of replacing a component every 500 hours, HUMS can indicate precisely when maintenance is required, reducing unnecessary maintenance and saving costs.

To make this intelligence more practical, HUMS provides users with a specific checklist outlining the steps to correct equipment issues. These insights are tailored to particular users, such as commanders, operators, and technical teams, to ensure the information is actionable and relevant.

Notably, HUMS cannot operate in isolation; it relies on a comprehensive set of technologies to reach its full potential. First, embedded sensors must be rugged, accurate, and capable of transmitting real-time data. Next, AI and machine learning platforms must process the data from the sensors and generate actionable alerts. Finally, secure, high-speed communications must connect these systems to commanders and support units.

When these pieces come together, predictive maintenance becomes a force multiplier. HUMS detects the problem, AI predicts when it will fail, and networked systems ensure the correct parts are ready before the failure occurs. However, even with the right technology in place, sustainment depends on reliable access to the parts and materials needed to keep systems running.

Fortifying the U.S. Defense Industrial Base

The U.S. defense industrial base is undeniably strained. Manufacturing timelines can’t always meet equipment needs, and many critical components, like batteries, sensors, and microelectronics, are sourced from unstable suppliers.

Without a reliable supply chain, the benefits of predictive maintenance and HUMS are futile. That’s why the U.S. must not only adopt HUMS and predictive systems, but also expand and secure its production base. Some ways to do so include onshoring key manufacturing capabilities and incentivizing commercial suppliers to enter the defense market.

Commercial components, such as those used in robotics, UAVs, and vehicle electronics, must be sourced from trusted suppliers. In our modern, globalized economy, national security depends as much on the supply chain as it does on battlefield tactics.

Defense leaders should consider alternative sources to help diversify traditional supply chain sources and techniques. This includes leveraging foreign-developed technology that has been adapted to specific platforms. By implementing strong integration programs using techniques such as Model-Based Systems Engineering, integrators can better understand how components and systems can be brought together to the greatest effect. This approach leverages existing, proven technologies.

Looking Ahead

Predictive maintenance, powered by technologies like HUMS, is essential to military readiness. It allows the U.S. military to maintain complex systems more efficiently, reduce unplanned failures, and keep equipment operational when it’s needed most.

HUMS offers the opportunity to change the way maintenance is planned and executed fundamentally. For example, the maritime industrial base that supports operations and maintenance for the Navy is not operating significantly differently than it did during the Cold War. While efforts have been made to improve readiness, there are still lengthy periods of shipyard work that reduce the fleet’s operational availability and increase total costs. A dynamic maintenance program, enabled by effective monitoring and analysis, is inherently beneficial to achieving shorter shipyard stays and lower overall maintenance costs.

As operational demands increase and logistics become more complex, the ability to monitor, analyze, and act on equipment health data in real-time is critical. HUMS gives commanders and maintainers the tools to stay ahead of failures rather than react to them. However, to unlock the full value of HUMS, the U.S. must invest in a resilient industrial base and secure supply chain.

About the Author:

Marc Steiner is the CEO of Advanced Defense Technologies, Inc. (ADTI). In this role, he ensures ADTI is equipped to deliver cutting-edge technologies that advance aerospace and defense missions. Before joining the private sector, Marc served as a U.S. Navy officer and Fleet Support Branch Chief at the National Geospatial-Intelligence Agency.

Marc Steiner is the CEO of Advanced Defense Technologies, Inc. (ADTI). In this role, he ensures ADTI is equipped to deliver cutting-edge technologies that advance aerospace and defense missions. Before joining the private sector, Marc served as a U.S. Navy officer and Fleet Support Branch Chief at the National Geospatial-Intelligence Agency.

For over three decades, ADTI has been manufacturing and delivering electronic components and systems to the world’s leading armored vehicle defense industries. Together with its parent company, IMCO Industries Group, ADTI’s decades of operational expertise ensure optimal HUMS implementation.