TopLine Urges Defense Contractors to Take Control of FPGA Column Attachment

TopLine Corporation, a producer of components for ruggedized semiconductors, urges defense contractors to plan for delivery delays of critical military components, specifically Field Programmable Gate Array (FPGA) devices, in the event FPGA makers suddenly cannot provide FPGAs with solder columns.

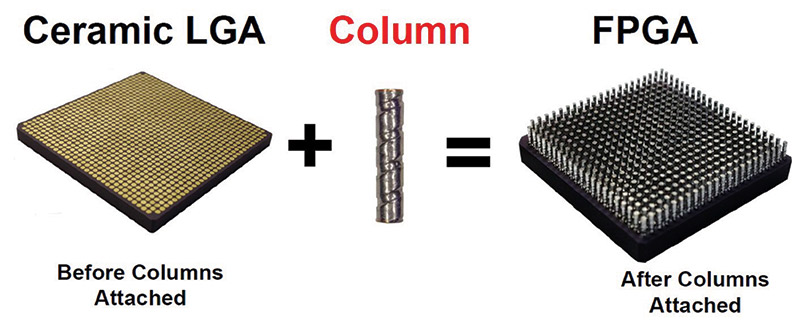

“The defense industry should be concerned about its dependency on a single source vendor to attach copper-wrapped solder columns to FPGA devices as recorded in the Qualified Manufacturer List (QML-38535) published by an agency of the Department of Defense. Military-grade FPGA devices used for defense applications cannot function without solder columns,” states TopLine CEO Martin Hart. “Defense contractors are better served by bringing control of attaching such solder columns in house rather relying on the current single-source subcontractor to provide this service. Delivery of warfighters and aviation systems may be interrupted without solder columns to connect FPGA components to Printed Circuit Boards (PCBs),” said Hart.

“TopLine is a National Resource as an American manufacturer of copper-wrapped solder columns. We can fully support defense contractors who want to take full control of attaching copper-wrapped columns on FPGA devices by themselves. Defense contractors with in house capability to attach solder columns can have FPGA devices ready in days rather than waiting for months. The current monopoly supplier has no incentive to deliver column attachment services quickly because no competition exists,” adds Hart.

Hart suggests that major customers of FPGA devices such as Boeing, L-3 Harris, Lockheed Martin, Northrop-Grumman and Raytheon, would all benefit by developing their own internal capability to attach solder columns as the last step in getting FPGA devices to be PCB ready.

“The U.S. industrial base benefits by executing a risk mitigation strategy to take control of solder column attachment to ensure a resilient capability to produce critically needed FPGA components. By acting now to qualify their column attachment process, defense contractors can reduce the risk of a future FPGA shortage instead of waiting for a sudden disaster to strike, potentially costing hundreds of millions of dollars in delays,” concludes Hart.