Revolutionizing Aerospace Power Management: Advancements in Smart Contactors

Aerospace power systems are at the crux of an emerging revolution. As our skies become populated with sophisticated, increasingly electrified aircraft, a wide array of drones, and electric vertical takeoff and landing (eVTOL) vehicles, a fresh approach to aerospace power management is paramount. Amid this innovative flurry, contactors have steadily evolved into intelligent power management tools that extend beyond traditional power control, providing insightful diagnostic information that enhances system reliability.

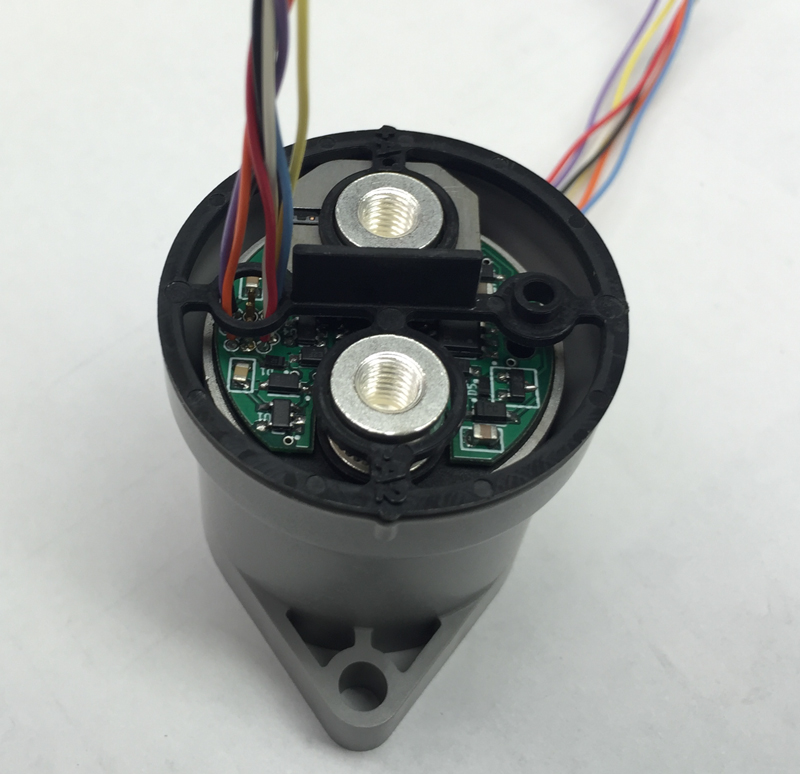

Traditionally seen as simple electromechanical switches, contactors have undergone a remarkable transformation. Contemporary contactors feature integrated electronics, sensors, and communication capabilities, redefining their role in aerospace applications. Advanced contactors, commonly referred to as “smart contactors,” have shown promise in efficiently managing power flow and providing fault detection and prediction, thus ensuring optimal performance.

Monitoring and Control: The Backbone of Power Management

Today’s intelligent contactors seamlessly monitor and control power flow by leveraging various sensing techniques. Resistive sensing, for instance, uses a precision resistor to gauge current flow. Despite its accuracy, resistive sensing has some drawbacks, such as generating excessive heat, particularly in high-current contactors. Other approaches, like current transformers (CTs) and Hall-effect sensors, measure the magnetic field created by the current to monitor power flow.

Hall-effect sensors, in particular, offer several benefits, including excellent isolation between primary and secondary circuits, high accuracy, superior dynamic performance, and exceptional reliability. Despite the type of sensor chosen, supporting electronics are vital to collecting information and making intelligent decisions on system configuration.

Smart contactors can react autonomously to overload fault conditions, delivering rapid response times. What’s more, these contactors can be customized for specific load requirements through various means like connector pin programming, DIP switches, external resistor additions, or software coding, underscoring their flexibility.

Broadening Horizons: Beyond Overcurrent Protection

While overcurrent detection is a primary role for smart contactors, these advanced devices can also detect various other fault types. For instance, phase faults, including loss of phase and improper phase rotation, can be sensed to ensure efficient three-phase power delivery. Leakages and ground faults can be detected via multiple sensors along the wiring path, helping identify weaknesses and prevent electrical failures.

Arc fault detection is another critical feature of modern smart contactors. Traditional protective devices often overlook these faults, which can lead to overheating. Arc faults detection is a powerful tool that allows preemptive measures, averting potential system damage.

Redefining Contactors: Solid-State Revolution

The advent of power semiconductors has paved the way for solid-state relays, an exciting development for contactor technology. By replacing power contacts with metal-oxide-semiconductor field-effect transistors (MOSFETs), the solid-state approach promises enhanced reliability due to the elimination of moving parts. However, the increased thermal output of these devices necessitates careful heat management strategies to avoid failure.

The “hot-switching” challenges associated with contactors have gained prominence with the industry’s push toward more electric aircraft (MEA). This is where hybrid contactors come into play. A hybrid contactor combines the low ON resistance of an electromechanical contactor with the non-arcing power switching of power electronics. This technology can substantially increase the hot-switching life for high-voltage DC (HVDC) contactors.

Another promising innovation is the Solid-State Power Controller (SSPC), which merges a complete solid-state power switch with monitoring and communication features. These intelligent devices can be configured remotely, improving system reliability and availability.

From Sensing to Prediction: The Future of Contactors

Smart contactors and SSPCs can collect and analyze crucial operational data with integrated microcontrollers, enabling fault prediction and offering timely, flexible responses. Monitoring real-time current and voltage levels can provide insight into the contractor’s health and the overall aircraft electrical system. For instance, observing data related to running currents, temperature, and the number of cycles can enable predictive maintenance, thus extending the life of the contactor.

This data-driven approach extends beyond contactor health. For instance, initial power-up current draw can reveal inrush currents to motors or pumps, providing insight into components like bearing wear. This intelligence can help schedule timely lubrication and maintenance tasks, preventing potential component failure.

This operational data can reveal significant insights into system health when compared over time. Spotting trends in sensor data can enable early detection of faults in the wiring system, further ensuring system reliability.

Harnessing Data: Enhancing System Health and Predictive Maintenance

Aerospace is a domain that presents several unique challenges. Contactors must function in demanding environments, and ensuring their optimal performance is crucial for safe and efficient aircraft operations. A comprehensive monitoring and data analysis approach can provide a holistic understanding of the system’s health.

The concept of harnessing data for better predictive maintenance can be scaled up, using multiple devices and additional sensors throughout the wiring system to create a holistic “big picture” overview. This data can then be utilized for advanced analysis and prediction, fostering a comparison of conditions across the system and allowing for the anticipation of potential problems.

Integrated Assemblies: The Future of Aerospace Power Management

As contractors become increasingly complex and sophisticated, many industry players opt for custom-designed, application-specific power panels as an all-encompassing power management and distribution solution. These panels, which house relays, contactors, and control electronics, can provide advanced monitoring and control capabilities. These plug-and-play solutions exemplify the future of power distribution in the aerospace industry, integrating all required components in a compact, custom package.

Embracing Intelligent Power Management for Aerospace Applications

In a rapidly evolving aerospace landscape, smart contactors, hybrids, and SSPCs are revolutionizing power management. By harnessing the power of integrated electronics, sensors, and advanced communication features, these next-gen devices are central in power distribution, fault management, and system health analysis.

In this era of advanced digital technology, embracing these technological strides is vital, redefining the potential of power management in the aerospace industry. As the skies become more congested with diverse aircraft types, including those operating new missions, ensuring efficient power management and fault prediction will be key to maintaining the high standards of safety and reliability for which the aerospace industry is renowned.

Technology often has a habit of advancing at an ever-accelerating pace, especially in a field as dynamic and critical as aerospace. The future lies in smart contactors and SSPCs, revolutionizing power management by marrying traditional contactor technology with advanced digital capabilities.

A significant shift observed in this domain is the move toward hybrid contactor designs. These intelligent devices blend the low ON resistance advantage of traditional electromechanical contactors with power electronics’ non-arcing power switching capabilities. This combination eliminates a significant wear-out mechanism within the contactor. It drastically enhances the hot-switching life for High Voltage Direct Current (HVDC) contactors, providing an attractive solution for applications requiring numerous hot-switching cycles.

On the other hand, SSPCs are emerging as highly effective power management tools. An SSPC combines a full solid-state power switch and multiple monitoring and communications capabilities. This combination offers an integrated overcurrent trip curve that guards the wiring interconnects and the load against excessive current draw or short circuits. SSPCs can communicate for command and status over a vehicle data bus, enhancing system reliability and availability. High voltage SSPCs even come equipped with a built-in pre-charge feature, which allows efficient power-up while reducing surge currents.

The transition from traditional contactors to these advanced technologies is driven by the constant quest for efficiency, reliability, and longevity in the aerospace sector. These solutions offer enhanced performance, and their intelligent, data-driven operations allow for predictive maintenance, thus reducing unplanned downtime and extending system life.

As a new era emerges, it’s evident that the aerospace industry is standing on the cusp of a significant shift in power management. Smart contractors, hybrids, and SSPCs, coupled with advanced data analysis, are poised to redefine the understanding of system health and the application of predictive maintenance. Such advancements are expected to bolster further the industry’s laudable commitment to safety, reliability, and efficiency in the skies.

Connect with Karl Kitts at www.DesignSmarterFaster.com.